Cable Mesh Suppliers In South Africa

Wire mesh is fabricated by the intertwining, weaving, or welding of wires of various thicknesses to create proportionally equal parallel rows and intersecting columns. Also known as wire fabric, wire cloth, or hardware mesh, the production of wire mesh involves the weaving of wire on industrial looms, leaving square or rectangular gaps between the wires. Welded wire mesh or fabric is manufactured using an electric welder that joins parallel longitudinal wires where the wires intersect.

Types of Wire Mesh

The different kinds of wire mesh are classified by how they were made, their qualities, function, and weave patterns. Each of the various types is designed to meet the strength, weight, and finish requirements of a project or application. The determining factors regarding the type of wire mesh that will be used are its finish, type of metal, and type of pattern, with finish and metal being the major determining factors.

Welded Wire Mesh

Welded wire mesh has square-shaped wire patterns. The welding process forms a strong mesh, which makes it perfect for security fencing, storage and racking in warehouses, storage lockers, animal holding areas in veterinary clinics and animal shelters, room divisions, and traps for pests.

Welded wire mesh is:

- Durable and capable of withstanding changes in weather

- Held securely and firmly in place without creep or shifting

- Customizable to fit any dimensional needs or specifications

When welded wire mesh is made from stainless steel, it has stainless steel’s durability and corrosion resistance.

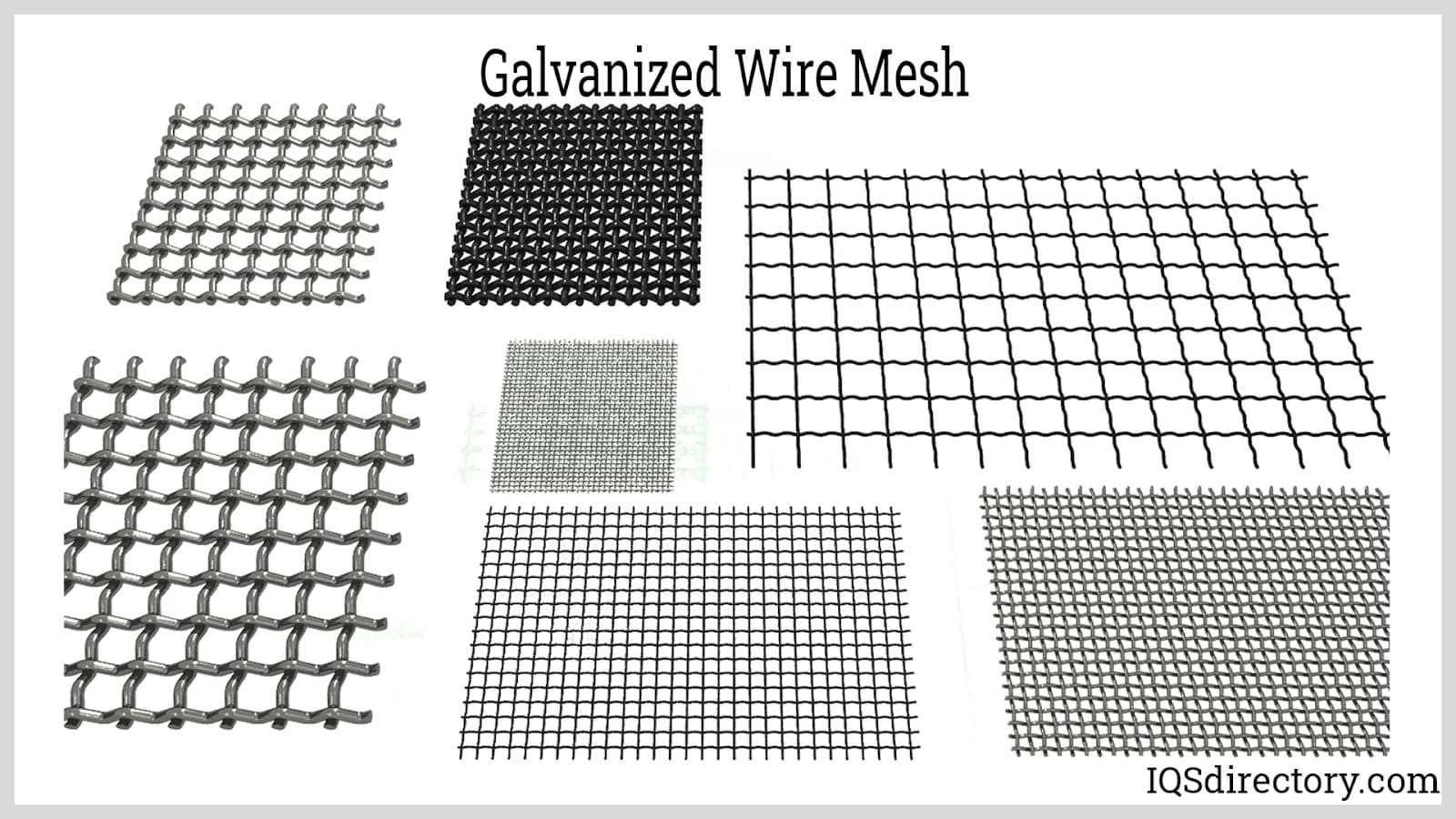

Galvanized Wire Mesh

Galvanized wire mesh is made from plain or carbon steel wire that is galvanized, a process that involves applying a zinc coating. The zinc layer acts as a shield that protects the wire mesh against rust and corrosion. Galvanized wire mesh can be welded or woven using galvanized wire or plain steel wire that is galvanized after being woven or welded. Of the two processes, galvanizing the wire mesh after it is processed initially costs more but produces a higher-quality wire mesh.

Galvanized wire mesh is ideal for fencing for agriculture and gardening, greenhouse, architecture, building and construction, security, window guards, and infill panels. Due to its cost, it is one of the more widely used of the different types of wire mesh.

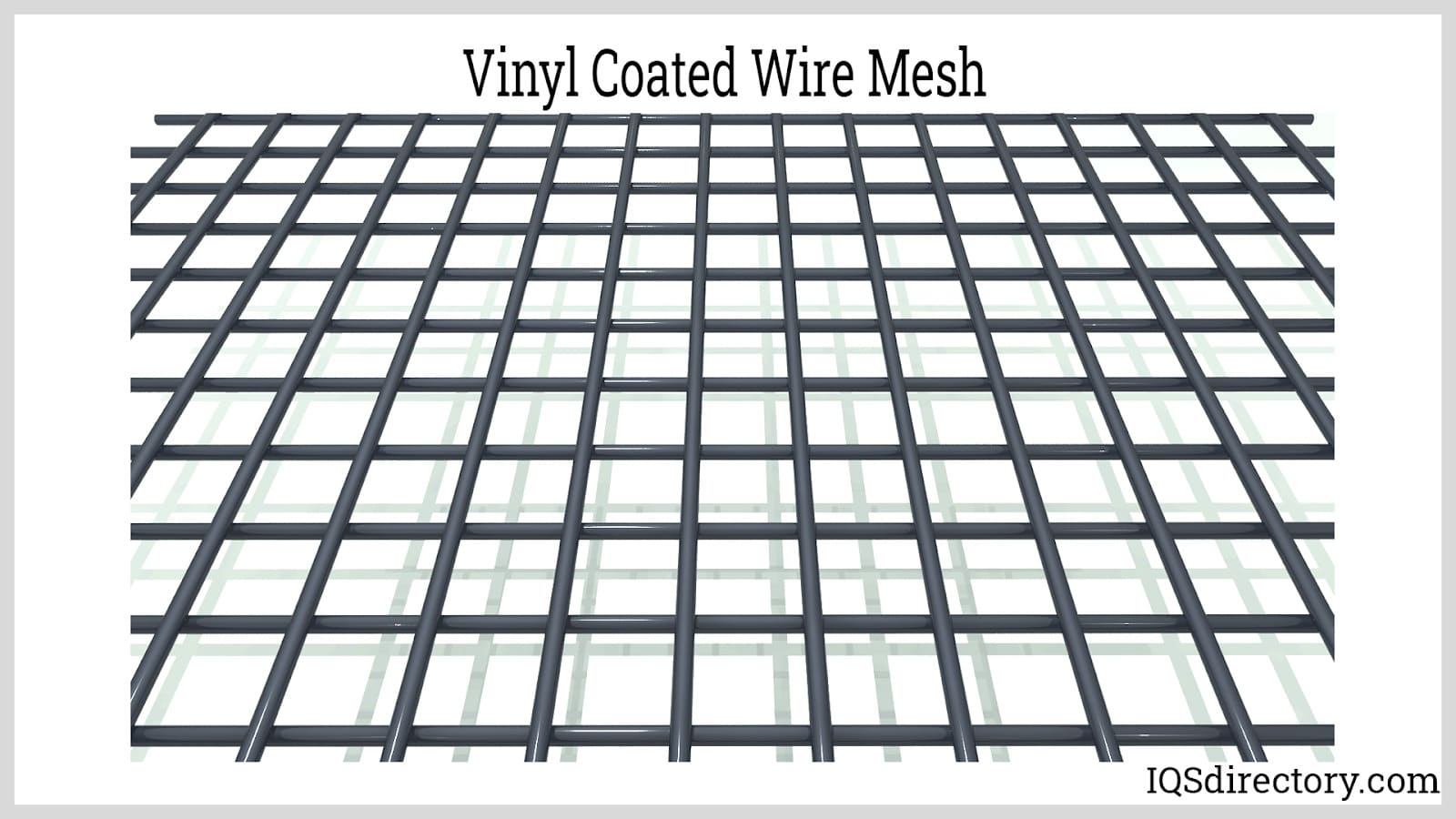

Vinyl-Coated Wire Mesh

The application of a vinyl coating to welded or woven wire mesh creates a strong barrier for very flexible wire mesh. Vinyl-coated wire mesh is stable over a wide range of temperatures, is not degraded by exposure to the sun, and is resistant to scrapes, abrasions, and impact.

The vinyl coating of wire mesh gives the impression that the mesh is made of plastic and is sometimes referred to as plastic mesh. Aside from giving wire mesh an appealing appearance, vinyl-coated wire mesh is long-lasting, durable, and rust- and corrosion-resistant. It seals the wires from water and other intrusive elements.

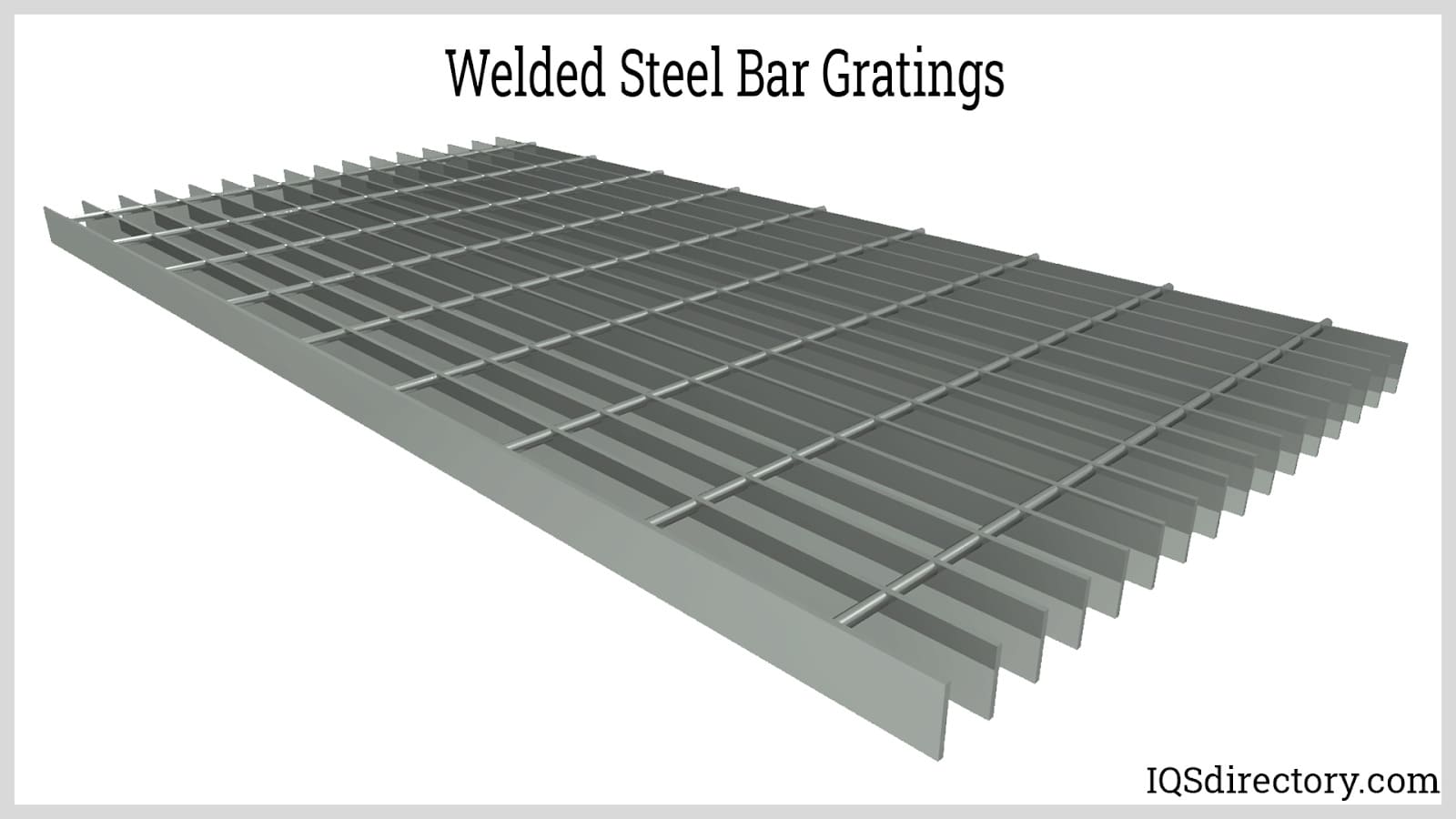

Welded Steel Bar Gratings

Welded steel bar gratings are produced by forge welding at extremely high temperatures. In this process, perpendicular bars are drawn across a parallel series of rectangular bars, connecting the bars together. The process creates a fused, long-lasting connection that can withstand the most demanding and hazardous conditions. The steel for welded steel bar gratings is carbon steel or stainless steel and is exceptionally durable, strong, and rigid.

Designed to carry heavy workloads for many years, welded steel bar grating is used for landing mats, bridge decking, ventilation grills, ramps, sidewalks, and industrial flooring. Panels are produced in two to three-foot widths in two-foot lengths in a wide range of bar sizes, from 1” to 6” depths and 0.25” up to 0.50” thicknesses.

Stainless Steel Wire Mesh

Stainless steel wire mesh has all of the positive properties of stainless steel and provides high-quality protection and performance. Steel is widely used to produce wire mesh but rusts easily when exposed to the air. Stainless steel, which has the same compounds as steel, has chromium added that is rust-resistant and protects stainless steel from oxidation.

How do I identify wire mesh?

To determine mesh or mesh count, start from the center of one wire and count the number of openings to a point exactly one linear inch away. For example, No. 4 mesh (or 4 x 4 mesh) indicates that, in one linear inch, there are four openings.

What are the benefits of wire mesh?

Wire mesh panels are used to hold material and lift heavy weight, reducing the otherwise heavy reliance on on-site manpower. Because of their flexibility and capability of handling weight, wire mesh panels can be used to move raw material around without any risk of them getting loose (and thus being a hazard).